Jeff Dahn obtained his B.Sc. from Dalhousie University (1978) and his Ph.D. from the University of British Columbia in 1982. Dahn then worked at NRC (Canada) (82-85) and Moli Energy (85-90) before taking up a faculty position at Simon Fraser University in 1990. He returned to Dalhousie in 1996. At Moli, he did pioneering work on lithium-ion batteries.

Single crystal Ni-containing cathodes - A conversation with Prof. Jeff Dahn

Professor Jeff Dahn, at the Department of Physics and Atmospheric Science, Dalhousie University in Nova Scotia, Canada explains how single crystal technology is proving to be a promising solution to the challenge of overcoming range anxiety which is high on the agenda of electric vehicle manufacturers and battery developers.

Dahn was appointed as the NSERC/3M Canada Industrial Research Chair in Materials for Advanced Batteries at Dalhousie University in 1996, a position that he held until 2016. In 2016, Dahn began a research partnership with Tesla as the NSERC/Tesla Canada Industrial Research Chair. He is the author of 730 referred journal papers and 73 inventions issued or filed.

Dahn’s research has been recognized by numerous awards including a Governor General’s Innovation Award (2016) and the Gerhard Herzberg Gold Medal in Science and Engineering (2017), Canada’s top science prize. He is the only person to have been awarded both awards this far.

Dahn was appointed as an Officer of the Order of Canada in Nov. 2020.

A Conversation with Prof. Jeff Dahn

This discussion is complementary to the article 'A new crystal clear solution - Innovation that will drive electric vehicles to greater lengths' published in Nickel Magazine 35 - vol 3, page 6.

Nickel Institute: What are the fundamentals of single-crystal technology?

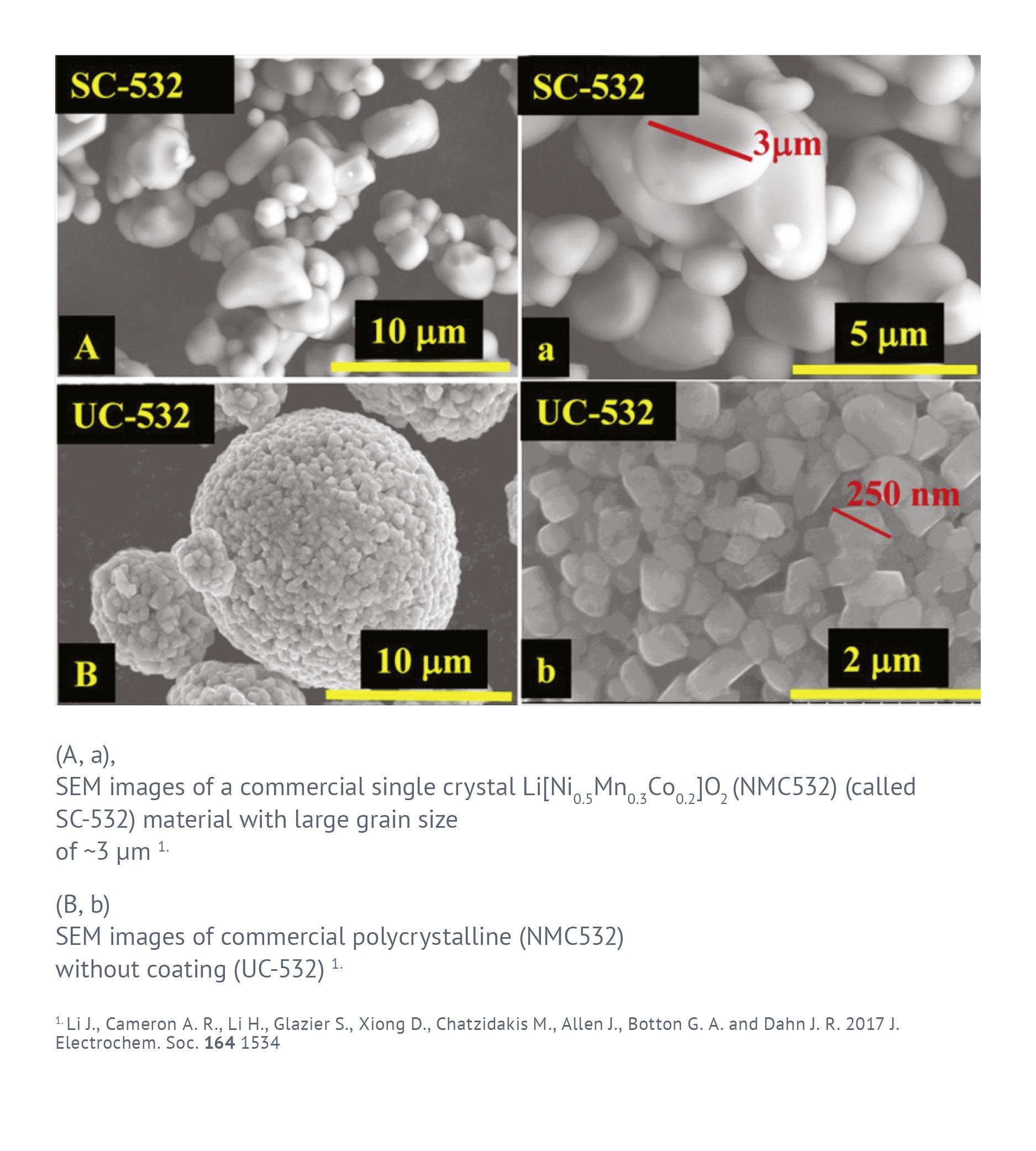

Prof. Jeff Dahn: Typical positive electrode material particles are a secondary particle made up of very many smaller primary particles and these particles are generally oriented in sort of random directions, so the crystal axes of one primary particle are not parallel to the crystal axes of another. When a positive electrode material intercalates and de-intercalates lithium, its volume changes and it changes anisotropically. The changes in the direction perpendicular to the layers or parallel to the c axis are large. So, if two primary particles are touching against each other, there is this volume mismatch that takes place and that can lead to microcracking of the secondary particle into many small pieces. Then you lose electric contact and start to lose access to the positive electrode active mass through that process. A single crystal particle, by contrast, is one crystallite that might be a two to three-micron particle, that's an entire single crystal, where there are no grain boundaries at all so the whole thing expands and contracts as a unit. Then what you have to do is to maintain the electric connection to these particles as they expand and contract. That’s relatively easy to do with electrode formulations that have carbon black and elastomer binder or even a slightly elastic binder. Using a single crystal allows you to maintain a 100% connection to the positive electrode active mass throughout the charge-discharge. It’s quite incredible.

NI: It is evident that single crystals can tolerate a lot more cycling but given that the crystal still expands, will they have a finite life before it starts to physically break down?

J.D.: We have taken SEM images of single crystals materials after 5300 cycles and we don’t see any evidence of microcracking. I am not sure if it actually will ever break down unless you do things like drive up an enormous rate where you would have a volume mismatch between the outside and the inside of the crystallite and maybe it would fracture. But for our C-rate cycling, after 5300 cycles, we don’t see any cracking at all.

NI: Cycle life is contingent upon physical durability however other mechanisms limit the cycle life such as decompositions and redox reactions that can occur on the surface of the material, how does the single-crystal technology affect that?

J.D.: The single crystal plays a relatively minor role in changing those processes. In the end, in our single-crystal NMC cells that we are testing, the main failure mode is the loss of Li inventory in the negative electrode SEI (Solid Electrolyte Interphase). This is just the fact that the lithiated graphite is highly reactive and therefore, the SEI slowly thickens over time. So, you basically remove all the failure mechanisms at 4.3 V and below that can be attributed to the positive side.

We have taken SEM images of single crystals materials after 5300 cycles and we don’t see any evidence of microcracking.

It’s a very simple argument for why the single crystal succeeds so if you make these single crystal particles, they should succeed however you do it.

NI: How does this process work among the various NMC cathode materials (NMC 532, NMC 622, NMC 811) especially when you go to higher Ni content?

J.D.: In the work that we published in late December 2019/winter 2020, we showed a comparison of single crystals of NMC 532, NMC 622 and NMC 811. SEM cross-sections of cathode particles from single crystal NMC 811 were taken after 1100 cycles. Those still looked fine without cracking. I don’t think there is any good data available yet on very-high Ni content single crystal material.

NI: You have created this single crystal with a standard co-precipitation process but there are other processes being worked on by other groups. What are the differences in these processes?

J.D.: I have only looked at materials prepared in house by methods of the same type. We have looked at industrially prepared materials and I have no idea what they did to make their material. It’s a very simple argument for why the single crystal succeeds so if you make these single crystal particles, they should succeed however you do it.

NI: Concerns have been expressed with regards to the cost for single crystals. Is research ongoing in your lab for reducing the cost of large-scale production of single crystals?

J.D.: When we make single crystals here, all we are doing is changing a little on the precursor side which I don’t think adds any costs at all and then heat treating to a slightly higher temperature to grow the single crystals. I don’t think this will add too much to the cost. I have heard people say 2-3 % cost premium. There is nothing fundamentally different about the whole process. China is using thousands of tons per year of single crystal 532, 622, 811… If it was highly expensive, that wouldn’t be happening.

Q: So, is single crystal cathode material being commercially manufactured right now?

A: Absolutely

NI: How did the million-mile battery term come about?

J.D.: Our goal here is to help lower the cost, increase the energy density and improve the lifetime of Li-ion cells and this just kind of fell out of our work. We didn’t call it the million-mile battery. We published a paper and one sentence of the abstract said ‘we show that batteries like this could power electric vehicles for a million miles.’ Nowhere did we call this thing the million-mile battery. That was picked up by the media!

It goes to show you that there is a value in running tests for a very long duration. The cells that are highlighted in this so-called million-mile battery paper, some of them are still on test. I was looking at them the other day. The room temperature cells are out now to about 9500 cycles with less than 10 percent loss so they are really pretty incredible.

NI: What’s the cycle rate on that?

J.D.: Three years of running at 1C-1C.

NI: this is impressive! With your supersensitive coulomb counting tester, can you predict out to these cycling levels?

J.D.: It gets tough once things get this good. We can probably tell you from the ultra-high precision charger that this is a really good system that it’s going to go thousands of cycles but distinguishing 10000 cycles from 20000 cycles with methods we have in hand is not trivial. Things are getting to be really good. We just dedicated maybe 50 chargers out of our bank of 1700 for these kinds of measurements to see how long they can go. They might outlive me for all I know. They could well outlive the chargers, I think that’s a very real possibility.

Some of the room temperature cells from our so-called million-mile battery paper are out now to about 9500 cycles with less than 10 percent loss, so they are really pretty incredible.

NI: With this kind of durability, does it open up the window for decreasing the amount of other materials like the additives or dopants that are used for durability?

J.D.: No, you still need additives to deal with the negative electrode side. Some of the single-crystal materials that are industrially available are coated with something. We wrote a paper that compares single-crystal materials that are coated with a proprietary coating and uncoated materials. We showed that with the right electrolyte additives, the uncoated material could be equivalent to the coated one. The coatings seem to make them quite tolerant to the primitive electrolyte mixtures.

NI: Currently, ICE vehicles lifetime is from 250 K to 300 K miles, the one million miles is three times better than this maximum. An ICE vehicle has to be maintained a couple of times a year, in terms of an EV with this kind of battery, how would the maintenance be?

J.D.: The whole issue about EV maintenance is pretty interesting. If you speak with Tesla owners or probably on the Tesla website, the first service for a Tesla is after four years. No oil changes, no break changes. EVs use regenerative breaking the majority of the time, you use your friction breaks rarely, only when you come to the dead stop or stoplight. I was driving with a friend who had a Tesla Model X, he let me drive it, we went in the city for 10 km, stoplights, all kinds of things and the regenerative braking on that thing is so good. I think I touched the friction brakes about twice in a 10 km drive. You come to a stoplight, you just let go of the accelerator and you slow right down and ease in behind the car ahead of you and if you do the timing right, you barely touch the friction breaks. Definitely, the maintenance of EVs is going to be trivial compared to a gas car.

NI: We appreciate your time for this fascinating conversation.

J.D.: Thank you.