last revision: January 2021

Metals and alloys are ubiquitous and integral to modern life, so much so that they often go largely unnoticed in our daily lives (e.g., in applications such as architecture, buildings/construction, consumer products, healthcare, infrastructure, schools, transport). Yet, society is reliant on metals and alloys due to their properties such as durability, strength, and electrical conductivity.

Metals and alloys are crystalline in nature, often displaying similar characteristics and frequently being described collectively as “metals.” However, it is important to understand that they are different and distinct from one another. Metals are chemical elements (substances), each with its own unique characteristics (e.g., mass, melting point, chemical and physical properties).

While some metals are used in their pure (i.e., elemental) state, the majority are used in the form of alloys, mixtures of a metal containing two or more [chemical] elements(1) (usually other metals). Alloying can impart significantly different characteristics that overcome some of the limitations associated with the use of their pure metal ingredients.

|

|

This is the third in a series of fact sheets addressing issues specific to the evaluation of risks to humans associated with nickel-containing substances and materials. The fact sheets are intended to assist the reader in understanding the complex issues and concepts associated with assessment of human health hazards, dose-response relationships, and exposure by summarizing key technical information and providing guidance for implementation.

This material has been prepared for the general information of the reader and it is not intended to be medical or technical advice for specific situations. The publication is based on current scientific knowledge and while believed to be technically correct, it should not be used or relied upon in specific cases without first securing professional advice. Nickel Institute, its members, staff, and consultants do not represent or warrant its suitability for any general or specific use and assume no liability or responsibility of any kind in connection with the information herein.

NiPERA Inc. welcomes questions about anything stated in this fact sheet. For inquiries, please contact Katherine Heim, Ph.D., DABT at kheim@nipera.org.

There are many definitions of an alloy, developed for specific uses and applications, with no single definition fully describing these unique entities. The United Nations Globally Harmonized System of Classification and Labelling of Chemicals (UN GHS) defines alloys as follows: “An alloy is a metallic material, homogeneous on a macroscopic scale, consisting of two or more elements so combined that they cannot be readily separated by mechanical means(2).”

Unlike simple mixtures where there is no chemical reaction between the individual substances and the individual ingredients retain their own intrinsic properties(2),(3),(4), the ingredients of alloys interact with one another by forming chemical bonds that confer different properties on the alloy compared with those of the ingredients alone. Thus, alloys are considered to be “special mixtures” with their own intrinsic properties that differ from those of their ingredient substances.

This represents a challenge because the properties of the individual alloy ingredients and their respective concentrations are thus not reliable indicators of the physico-chemical properties and toxicity associated with the alloy itself.

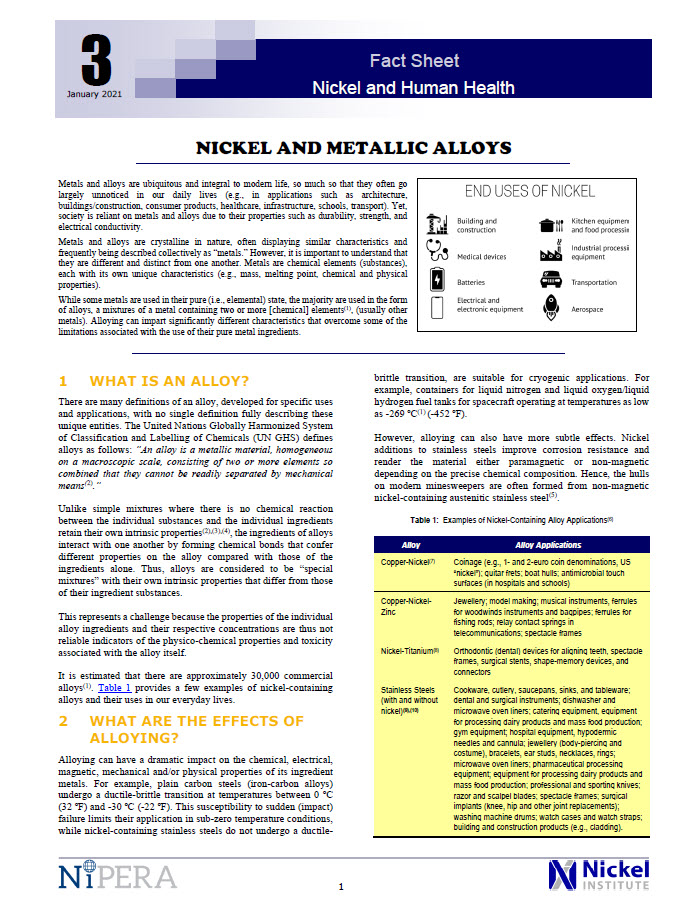

It is estimated that there are approximately 30,000 commercial alloys(1). Table 1 provides a few examples of nickel-containing alloys and their uses in our everyday lives.

Table 1: Examples of Nickel-Containing Alloy Applications(6)

Alloying can have a dramatic impact on the chemical, electrical, magnetic, mechanical and/or physical properties of its ingredient metals. For example, plain carbon steels (iron-carbon alloys) undergo a ductile-brittle transition at temperatures between 0 ºC (32 ºF) and -30 ºC (-22 ºF). This susceptibility to sudden (impact) failure limits their application in sub-zero temperature conditions, while nickel-containing stainless steels that do not undergo a ductile-brittle transition are suitable for cryogenic applications. For example, containers for liquid nitrogen and liquid oxygen/liquid hydrogen fuel tanks for spacecraft operating at temperatures as low as -269 ºC(1) (-452 ºF) require these alloys.

However, alloying can also have more subtle effects. Nickel additions to stainless steels improve corrosion resistance and render the material either paramagnetic or non-magnetic depending on the precise chemical composition. Hence, the hulls on modern minesweepers are often formed from non-magnetic nickel-containing austenitic stainless steel(5).

With the exception of a few light metals such as calcium, potassium, and sodium that react vigorously in the presence of water, most metals and alloys are generally considered to be insoluble in water. However, metals and alloys undergo corrosion, to a greater or lesser extent, in the presence of moisture, water, or other aqueous media.

Metal ion release occurs as a result of corrosion processes that take place at the surface of metals and alloys (i.e., at the interface with an aqueous medium or biofluid). These processes are driven by energy derived from chemical and electrochemical reactions that release ions from their metallic bonds. Figure 1 illustrates the basic corrosion/metal ion release mechanisms that occur when iron, or steel, is exposed to an aqueous medium. The key elements required for corrosion and metal release are: (i) an anode, (ii) a cathode, (iii) moisture or another aerated electrolyte, and (iv) the flow of electrons between the anodic and cathodic regions of the corrosion cell.

Figure 1: Basic corrosion/metal ion release mechanisms of iron or steel

(an alloy of iron and carbon) exposed to an aqueous medium

CC BY-SA-NC; Anonymous by request

In recent times, scientists have started to focus on the biological and environmental impacts of metal release from metals and alloys using artificial biofluids (such as simulated gastric and lung fluids, blood serum and sweat), artificial lake waters, or soil as test media. Such tests are generally referred to as bioelution or transformation tests, with results representing the bioaccessibility of the metals in the particular fluid as a conservative measure of bioavailability in relevant organisms.

Bioelution tests conducted on alloys in artificial biofluids or artificial lake waters demonstrate that, in some cases, greater quantities of metal ions are released from certain alloys (i.e., at an enhanced rate) when compared with releases from the pure metal ingredient under the same test conditions. This is due to the difference in electrical potential of the alloy ingredients that provide energy to drive the galvanic corrosion reaction and the release of metal ions(11).

As alloys are used in all aspects of modern life, there is a need to consider the potential implications for human health and the environment throughout the entire lifecycle of alloys.

In many jurisdictions around the world, alloys are considered to be mixtures for the purposes of risk assessment and chemical regulation [e.g., the European Union’s Registration, Evaluation, Authorisation and Restriction of Chemicals(3) (EU REACH) and Classification, Labelling and Packaging(4) (EU CLP) Regulations, UN GHS(2)]. It is assumed that the full concentration of each ingredient in the mixture is available to react with the environment and/or the organisms (including human beings) with which they come into contact. Therefore, for the purposes of risk assessment and hazard classification, the actual concentration of substances of concern in mixtures is used to determine whether the mixture is or is not hazardous and whether it should be classified for toxicity endpoints. For example, using concentration of ingredients as a basis for hazard classification, alloys containing more than 1% of a skin sensitizer (e.g., cobalt) would be classified as hazardous in accordance with the UN GHS(2).

However, the existence of a chemical matrix associated with alloys as special mixtures contradicts two fundamental principles governing the use of concentration as a suitable means of determining their status as hazardous or non-hazardous: (i) the alloy ingredients react together within the mixture and (ii) the individual ingredients do not necessarily retain their intrinsic properties. Therefore, the concentration of a substance in an alloy cannot be relied upon to provide an accurate estimate of relative toxicity or for hazard classification(12) and presents something of a problem for those seeking to regulate chemicals or predict toxicity. The EU CLP(4) addresses this issue for nickel-containing alloys and dermal sensitization by the application of the EN 1811(13) test method, as a refinement over the concentration approach, as described below under the heading “Regulatory Use of the Bioelution Concept for Human Health.”

Studies have provided a good general understanding of the individual toxicity profiles of metals. While there are a number of metals (e.g., cadmium, lead, mercury) that are known to be toxic and have no known physiological functions, there are other metals that are considered nutrients and are essential to the maintenance of various biochemical and physiological functions in humans and other living organisms. Essential elements are generally categorized as either macro (or major) minerals (such as calcium, magnesium, potassium, sodium, and zinc) or trace minerals (such as selenium, iodine, boron, and molybdenum). A deficiency or an excess in any of these minerals can lead to undesirable impacts on biological functions and toxicity. Therefore, since too high or too low values are toxic, lower metal release levels do not always represent a more conservative approach.

There are much fewer toxicity data available for alloys, since there are many alloys combining many metals. Any toxicity associated with alloys can be more complex due to the combination of ions released and their combined effects in humans and other organisms Metals and alloys have to undergo corrosion processes in order to release metal ions, unlike metal compounds that are more readily available for uptake and are naturally present in drinking water, beverages, and foodstuffs. In addition, the rate and extent of ion release may be influenced by electrochemical interactions at the alloy interface with biofluids(14),(15) and/or tissues within the exposed organism.

As the concentration of an ingredient in a special mixture (e.g., alloys) may provide unreliable hazard identification as well as any associated hazard classification, it was proposed to measure the amount of metal ions released as a means to estimate toxicity. Since the release of metal ions is needed for toxic reactions and is correlated with their toxicity potential(12),(16), metal ion release could be used to assess the expected toxicity profile of an alloy relative to that of its metal ingredients. This proposal led to the development of bioelution test methods applicable to alloys.

Bioelution refers to the in vitro methods used to measure the degree to which a substance (e.g., metal ion) is released in artificial biological fluids relevant to oral, dermal, or inhalation exposure. Bioelution tests are used to estimate a substance’s bioaccessibility (in the form of metal ions), i.e., its solubility under physiological conditions. Thus, these tests provide an estimate of the extent to which a substance is taken up by an organism and is available for metabolism and interaction at target organ/sites (e.g., kidney, skin); in other words, its bioavailability (17),(18). The conservative nature of oral bioaccessibility of metal/metalloids to predict in vivo bioavailability has been confirmed for several metals in soil studies(19). In the environment, toxicity has been linked to the bioavailability of metal ions at the target site of aquatic organisms and, which correlates with the metal release in a simulated aquatic environment.

Metal ion release and bioelution tests are not ‘new’ concepts and, in some regulatory arenas, they are already well-established in assessing the potential bioavailability of metals in environmental matrices and articles. The bioelution methods listed below have been formalized as standards for testing.

Regulators have been cautious in accepting metal bioaccessibility data for human health hazard identification due to the lack of internationally accepted standardized protocols, the complexity of bioavailability in humans compared to organisms in the aquatic environment, and because it challenges some of the well-established mixture rules related to the hazard classification of chemicals. In contrast to human health, hazard classification schemes are outlined in the UN GHS(2) and EU CLP(4) for metals and metal compounds in the aquatic environment. These schemes are based on the validated transformation/dissolution protocol incorporated in Organisation for Economic Co-operation and Development (OECD) 29 Guidance Document on Transformation/Dissolution of Metals and Metal Compounds in Aqueous Media(25).

REGULATORY USE OF METAL RELEASE DATA FROM ALLOYS FOR HUMAN HEALTH

The EN 1811 test method(13) provides an example of the integration of the use of bioaccessibility data generated by a bioelution test into regulation by the European Union (EU). This approach provides a control mechanism for nickel-containing articles intended for pierced parts of the human body (e.g., ear stud, eyebrow rings, etc.) and articles intended to come into direct and prolonged contact with the skin (e.g., jewellery, watches).

During the 1990s, the EU became concerned about the growing prevalence of dermal nickel allergy (i.e., sensitization) in young people(26),(27). Initially, a metal release limit of 0.5 µg/cm2/week was introduced via the EU “Nickel or Jewellery” Directive 94/27/EC for articles (products) intended to come into direct and prolonged contact with the skin(28) and a concentration limit of 0.05% nickel for articles that pierced the skin (e.g., stud earrings with piercing posts). However, it became apparent that some metallic materials (e.g., low sulphur nickel-containing stainless steels with >0.05% Ni) did not cause nickel allergic reactions and were safe for use in piercing exposure(26),(27). As a result, in the EU legislation published on 22 July 2004, [initially as an amendment and subsequently as a restriction under the EU chemical regulation REACH(3)], a metal release limit of 0.2 µg/cm2/week was introduced for piercing post assemblies (ear studs, etc.) when tested in accordance with EN 1811.

The nickel release rate (bioaccessibility data) for skin sensitization assessment was further applied for hazard classification for this endpoint in the mixtures rules of the Classification, Labelling, and Packaging Regulation(4). Nickel-containing metal mixtures (alloys with nickel as the only ingredient classified as a dermal sensitizer), tested in accordance with EN 1811 that comply with the specified nickel release limits (irrespective of their nickel content) do not need to be classified for skin sensitization(26). Thus, the unique properties of alloys, as described in this fact sheet, were fully recognized and a precedent was set for the future use of bioaccessibility data in the regulatory arena for human health. This situation is somewhat unique in that a threshold for dermal reactions to nickel exposure is available in humans.

For other health endpoints where toxicity is linked to bioavailability (e.g., acute oral toxicity), the relative release of the metal from the alloy and from the pure metal ingredient in the same physical form can be helpful in determining relative toxicity of alloys. The potential use of bioaccessibility data to refine hazard classification of alloys by calculating the relative bioaccessible concentration (RBC) based on relative metal release and comparing it to the GHS or CLP concentration limits for mixtures has been described by Heim et al.(16).

REGULATORY USE OF METAL RELEASE DATA FROM ALLOYS IN THE AQUATIC ENVIRONMENT

The aquatic hazard classification of metal-containing materials may be determined by testing in accordance with the Transformation/Dissolution Protocol (T/Dp)(25) and applying the hazard classification scheme described in the UN GHS and CLP guidance documents on classification of metals and metal compounds(29),(30). The T/Dp is used to evaluate the rate and extent of the dissolution of soluble metal ions and the results are compared to existing ecotoxicity data to assign the appropriate aquatic environmental hazard classification.

During the T/Dp validation project, the OECD Validation Management Group (VMG) evaluated the following test materials: cobalt oxide powder, lead oxide powder, nickel metal powder, and Nilo K (Fe-Co-Ni) alloy wire. Phase II of the evaluation examined the relevance of the T/Dp and, in particular, whether or not it had the power to discriminate between the environmental effects of different metals, metal compounds, and alloys. The Nilo K alloy proved to be particularly unreactive and OECD VMG judged the T/Dp to be insufficiently discriminating with respect to alloys and recommended that alloys should not be included as part of the UN GHS. In contrast, the EU CLP guidance(30) notes that testing of alloys using the T/Dp has demonstrated that this can be useful for alloy classification but additional guidance on this aspect is recommended.

In 2011, Skeaff et al.(31) reported the results of an interlaboratory test program to determine the precision of the UN T/Dp in classification of nickel metal powder, cuprous oxide (Cu2O) powder, tricobalt tetroxide (Co3O4) powder, and cuttings of Nilo K (Ni–Co–Fe) alloy in accordance with GHS Annex 10 guidance(25). These researchers reported that the T/Dp was capable of measuring the rate and extent of release of metals from metal-bearing substances with a wide range of reactivities (including the least reactive material Nilo K alloy) and concluded that T/Dp data could be linked to ERVs (Ecotoxicity Reference Values) to yield consistent GHS hazard classification outcomes for each substance.

In response to the extensive research with in vitro the oral fluid bioelution tests conducted by the metals industry and a lack of standardized protocols, the European Commission requested the European Union Reference Laboratory for alternatives to animal testing (EURL ECVAM) to develop a standardized and validated bioelution test for metals and alloys for the oral route of exposure. The industry submission included two main applications: i) for the grouping and read across of toxicity profiles of metal containing substances and mixtures and ii) for the assessment of matrix effects in alloys based on the comparison of the % relative bioaccessible concentration (RBC) with the % metal concentration. The ESAC (EURL-ECVAM Scientific Advisory Committee) external experts reviewed the protocol and its applications and supported its further development. The gastric bioelution protocol was later submitted by EURL ECVAM to the OECD in November 2019 for the development of a test guideline. This work is ongoing within the OECD Working Group of the National Coordinators for the Test Guidelines Programme.

The ESAC validated gastric protocol is already available for the generation of reproducible and reliable nickel (and other metal/metalloids) bioaccessibility data from alloys and reference ingredients. The development of an OECD Test Guideline would further solidify the application of this test. In turn, this could pave the way for the consideration of bioaccessibility data in the refinement of hazard classifications for the oral route of exposure (systemic effects) under the UN GHS(2) or the EU CLP(4). The experience gained during the development of a gastric bioelution test guideline could also help inform future standardized and validated human health bioelution protocols for other more challenging routes of exposure (e.g., inhalation).

Although industry has developed an impressive bank of bioelution test results in a variety of biofluids, there is a need to develop a structured database of reference materials and associated guidance documents that can be consulted by regulators, industry and other stakeholders to ensure that bioelution protocols are used appropriately and that test results are correctly interpreted and applied in order to assess the safety of the alloys and provide the maximum benefit to society.

- Alloys are not simple mixtures, but “special mixtures” with their own intrinsic properties that differ from their ingredient substances.

- The properties of the individual alloy ingredients and their respective concentrations are not reliable indicators of the physico-chemical properties and toxicity associated with the alloy itself.

- For the purposes of hazard classification, alloys are considered to be mixtures (with the single exception of the EU CLP classification for nickel metal for skin sensitization of alloys) and follow the mixtures’ rules for classification.

- Bioelution tests are useful to assess relative metal releases from alloys and their ingredients.

- As more research and validation are completed, the generation and use of bioaccessibility data is being considered for integration into guidance and regulations for different applications.

- Street A, Alexander W. 1999. Metals in the service of man. 11th edition. Penguin Books.

- Globally Harmonized System of Classification and Labelling of Chemicals (GHS). 2019. 8th revised edition. United Nations, New York and Geneva.

- European Commission (EC). 2006. No 1907/2006 of the European Parliament and of the Council on the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH). https://eur-lex.europa.eu/eli/reg/2006/1907/2014-04-10.

- European Commission (EC). 2008. No 1272/2008 on the classification, labelling and packaging of substances and mixtures (CLP Regulation). https://eur-lex.europa.eu/legal-content/en/TXT/?uri=CELEX:32008R1272.

- Sedriks AJ, Dudt PJ. 2001. Corrosion Resistance, Coating, and Magnetic Property Issues of Nonmagnetic Austenitic Stainless Steels for Ship Hulls. Corrosion 57:1 84-91.

- Nickel Institute. “Consumer Products: The Role of Nickel.” Nickel Institute website, Nickel Institute, November 18, nickelinstitute.org/about-nickel/consumer-products.

- Nickel Institute. “Applications of Copper-Nickel Alloys.” Nickel Institute website, Nickel Institute, November 2018, https://nickelinstitute.org/about-nickel/copper-nickel-alloys/applications-of-copper-nickel-alloys/.

- Nickel Institute. 2017. Nickel-containing medical materials: Improving lives. Nickel Magazine 32(3) 5-7, nickelinstitute.org/media/2699/nickelvol32no3fall2017_engfb-final.pdf.

- Stainless Steel World. “Overview of Typical Applications for Stainless Steels.” Stainless Steel World website, accessed January 2021, stainless-steel-world.net/basicfacts/overview-of-typical-applications-for-stainless-steels.html.

- Euro Inox, ed. 2009. Stainless Steel–When Health Comes First. Environment and Human Health Series, Volume 2. Euro Inox, Brussels. worldstainless.org/Files/issf/non-image-files/PDF/Euro_Inox/WhenHealthComesFirst_EN.pdf.

- National Physics Laboratory (NPL). 2020. Bimetallic Corrosion: Guides to Good Practice in Corrosion Control No. 5. Turnbull A, Hinds G, eds. National Physical Laboratory. Middlesex, UK. https://www.npl.co.uk/special-pages/guides/bimetallic-corrosion-gpg5.

- Nordheim E, Newson T. 2018. Chapter 13: Risk Assessment of Alloys. In: Risk Management of Complex Inorganic Materials, A Practical Guide, 1st Edition. Violaine Verougstraete, ed. London: Academic Press. pp. 219-244.

- European Committee for Standardisation (CEN). 2015. Reference Test Method for Release of Nickel from All Post Assemblies Which are Inserted into Pierced Parts of the Human Body and Articles Intended to Come into Direct and Prolonged Contact with the Skin; EN 1811:2011+A1:2015. European Committee for Standardisation. Brussels, Belgium.

- Wallinder IO, Herting G, Midander, K. 2006. Corrosion-induced metal release from stainless steel and its alloy constituents into different media. In: Stainless Steel Industry, Modern Metals Publications Ltd.

- Hedberg Y et al. 2010. Particles, sweat, and tears: a comparative study on bioaccessibility of ferrochromium alloy and stainless steel particles, the pure metals and their metal oxides, in simulated skin and eye contact. Integrated Environmental Assessment and Management 6:3 4546-68.

- Heim K et al. 2020. Bioaccessibility of nickel and cobalt in synthetic gastric and lung fluids and its potential use in alloy classification. Regulatory Toxicology and Pharmacology 110: 104549.

- Klassen CD. 2013. Casarett and Doull’s Toxicology: the basic science of poisons. New York, NY: McGraw-Hill Education.

- National Environmental Policy Institute (NEPI). 2000. “Assessing the Bioavailability of Metals in Soil for Use in Human Health Risk Assessments.” Bioavailability Policy Project Phase II Metals Task Force Report: National Environmental Policy Institute.

- Interstate Technology and Regulatory Council (ITRC). Bioavailability of Contaminants in Soil: Considerations for Human Health Risk Assessment. https://bcs-1.itrcweb.org/, accessed January 2021.

- European Committee for Standardisation (CEN). 2019. EN 71-3:2019, Safety of toys. Migration of certain elements.

- ASTM. 2017. ASTM F-963-17 Standard Consumer Safety Specification for Toy Safety. West Conshohocken, PA: ASTM International. https://www.astm.org/Standards/F963.htm.

- ASTM. 2014. ASTM D5517 Standard Test Method for Determining Extractability of Metals from Art Materials. West Conshohocken, PA: ASTM International. https://www.astm.org/Standards/D5517.htm.

- Bioaccessibility Research Group of Europe (BARGE). Barge website, bgs.ac.uk/barge/home.html, accessed January 2021.

- United States Environmental Protection Agency (US EPA). 2017. Method 1340. In Vitro Bioaccessibility Assay for Lead in Soil. US Environmental Protection Agency. SW-846 Update VI epa.gov/sites/production/files/2017-03/documents/method_1340_update_vi_final_3-22-17.pdf.

- Organisation for Economic Co-operation and Development (OECD). 2001. OECD Series on Testing and Assessment Number 29. Guidance Document on Transformation/Dissolution of Metals and Metal Compounds in Aqueous Media. ENV/JM/MONO(2001)9. Jul 23.

- Menné T et al. 1987. Patch test reactivity to nickel alloys. Contact Dermatitis 16:5 255-259.

- Haudrechy P et al. 1994. Nickel release from nickel-plated metals and stainless steels. Contact Dermatitis 31: 249-255.

- European Commission (EC). 1994. European Parliament and Council Directive 94/27/EC of 30 June 1994 amending for the 12th time Directive 76/769/EEC on the approximation of the laws, regulations and administrative provisions of the Member States relating to restrictions on the marketing and use of certain dangerous substances and preparations; Official Journal L 188 , 22/07/1994, Pages 0001-0002.

- Organisation for Economic Co-operation and Development (OECD). 2001. Series on Testing and Assessment No. 29, Guidance Document on Transformation/Dissolution of Metals and Metal Compounds in Aqueous Media, OECD, April 2001.

- European Chemicals Agency (ECHA). 2017. Guidance on the Application of the CLP Criteria. Guidance to Regulation (EC) No 1272/2008 on classification, labelling and packaging (CLP) of substances and mixtures. Version 5.0 July 2017. Annex IV: Metals and Inorganic Metal Compounds. Section IV.5.6.1 Classification of alloys and complex metal containing materials. pp. 602-603. European Chemicals Agency. Helsinki, Finland. https://echa.europa.eu/documents/10162/23036412/clp_en.pdf/58b5dc6d-ac2a-4910-9702-e9e1f5051cc5.

- Skeaff J et al. 2011. Advances in metals classification under the United Nations globally harmonized system of classification and labelling. Integr Environ Assess Manag 7(4): 559-76.